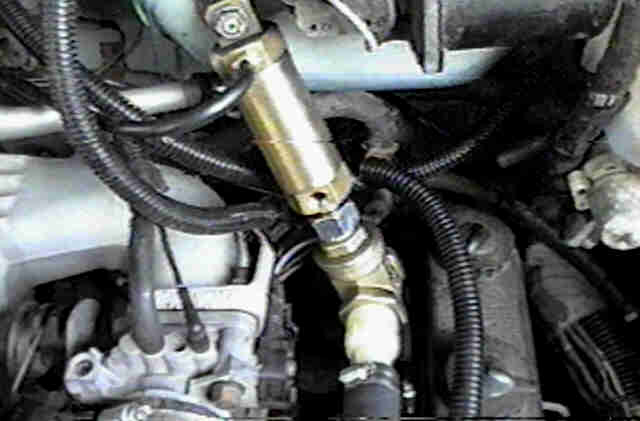

Above is the blow off valve I built.

I started with a standard $6.00 3/4 inch gate type water shut off valve.

I took the handle off, and took the valve apart. I drilled out

the brass gate in the valve and tapped it for a 3/8 inch bolt threads.

I then got a 1 inch bore, 2 inch stroke air cylinder from work. I

threaded the cylinder rod into the gate valve. I used a 5/8 coarse

thread nut to connect the cylinder to the valve, using the threads the

valve packing nut threaded to. I connect a vacuum line to the rear

port on the cylinder. Under vacuum, the piston is sucked up, opening

the gate valve. Under pressure, the piston is pushed out, closing the gate

valve. This happens at about 5 psi, and 10 in hg respectively.

I ran a 3/4 inch hose from my factory BOV to this valve. At anything

over 5 psi of boost in the intake, this valve closes, blocking off the

factory BOV, when the manifold is under a vacuum, this valve is open.

It should be noted that it "snaps" open and closed, but cannot be over

powered by too much boost.

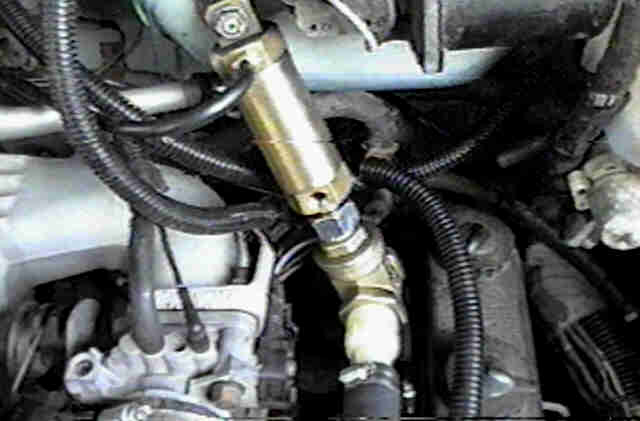

taken apart from right to left: air cylinder, 5/8 coupling nut,

valve top, 3/8 lock not on cyl. shaft,

valve gate, and valve body.

Installed with plastic hose conector and 3/4 inch hose over to factory

BOV.

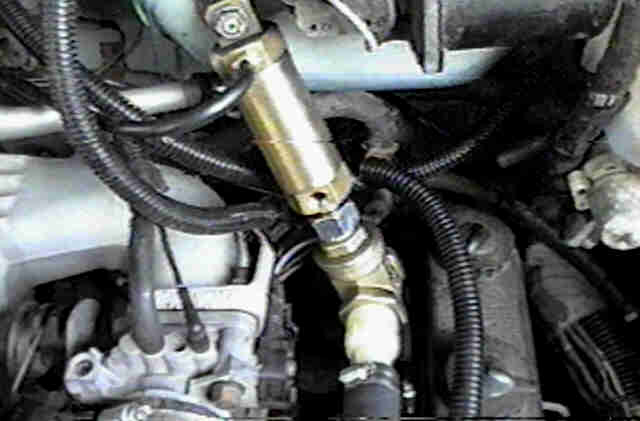

Notice pressure switch mounted on the AC connector. The silver

tube connected to the heater valve is actually 1/2" sweated copper tubing

painted silver. The factory steel lines rusted through.

Back to TURBOVAN!